Datasheet¶

Modules Overview¶

The SNAP Engine Model SM200 series includes the SM200P81 and SM200PU1 part numbers. They are IEEE 802.15.4, low-power, highly reliable solutions to embedded wireless control and monitoring network needs that require high data rates. The Model SM200 embeds Synapse’s SNAP OS, the industry’s first Internet-enabled, wireless mesh network operating system into the Atmel ATmega128RFA1 single-chip AVR® microcontroller with an integrated transceiver that delivers up to 2Mbits/sec. These low-cost modules can have current consumption as low as 0.37 µA to enable a new generation of battery-driven systems.

SNAP’s on-board Python interpreter provides for rapid application development and over-the-air programming, while Atmel’s low-power RF single-chip design saves board space and lowers the overall Bill of Materials and power consumption. The Model SM200 modules are approved as an FCC Part 15 unlicensed modular transmitters, as well as having CE Certification and IC Certification. The modules provide up to 16 channels of operation in the ISM 2.4GHz frequency band.

By default, the SNAP operating system automatically forms a mesh network with other nodes immediately on receiving power. No further configuration is necessary. Multiple unrelated SNAP networks can exist within the same area through several configuration options outlined in the SNAP User Guide.

Datasheet covers Part Numbers SM200P81 and SM200PU1:

34 GPIO with up to 7 A/D inputs

128k flash, 58.5k free for over-the-air uploaded user apps

Two UART ports for control or transparent data

- Low power modes:

0.37 µA with external interrupt

1.37 µA with internal timer running

Spread Spectrum (DSSS) technology

Up to 2 Mbps radio data rate

2.4 GHz RF Frequency

AES 128-bit encryption

Integrated chip antenna or U.FL connecter

Surface Mount, Solder-able

4K internal EEPROM

8 PWM outputs

The SM200 is also available with a U.FL connector. Contact Synapse for details.

Specifications¶

Table 2.1: SM200 Specifications at 25° C and 3.3V unless otherwise noted

Performance |

Outdoor LOS Range |

Up to 1500/2500 feet at 250Kbps |

Transmit Power Output |

3 dBm |

|

RF Data Rate |

250Kbps, 500Kbps, 1Mbps, 2Mbps |

|

Receiver Sensitivity |

-100 dBm (1% PER, 250Kbps) |

|

Power Requirements |

Supply Voltage |

2.0 - 3.6 V |

Transmit Current (Typ@3.3V) |

22.5 mA |

|

Idle/Receive Current (Typ@3.3V) |

20.5 mA |

|

Power-down Current (Typ@3.3V) |

0.37 µA |

|

General |

Frequency |

ISM 2.4 GHz |

Spreading Method |

Direct Sequence (DSSS) |

|

Modulation |

O-QPSK |

|

Dimensions |

29.8mm x 19mm |

|

Operating Temperature |

-40 to 85 deg C. |

|

Antenna Options |

Integrated Chip Antenna / External Antenna |

|

Networking |

Topology |

SNAP |

Error Handling |

Retries and acknowledgement |

|

Number of Channels |

16 |

|

Available I/O |

UARTS with HW Flow Control |

2 Ports |

GPIO |

34 total; 7 can be analog-in with 10bit ADC |

|

Agency Approvals |

FCC Part 15.247 |

FCC ID: U9O-SM200 |

Industry Canada (IC) |

IC: 7084A-SM200 |

|

CE Certified |

Certified to EN 300 328 Version 2.2.2 |

|

International Conformity Marks |

CE and UKCA |

|

You must preserve access to UART1 as a serial connection in order to be able to update firmware on the node, or to recover the node by forced script removal or parameter reset.

Module Pin Definitions¶

For pin locations, consult the SM200 Mechanical drawing later in this document.

Table 3.1: SM200PF1/PU1 Pin Assignments

SM200 Pin |

SNAPpy IO |

Pin Name |

Pin Description |

|---|---|---|---|

A1 |

GND |

Power Supply |

|

A2 |

VCC |

Power Supply |

|

A3 |

VCC |

Power Supply |

|

A4 |

24 |

PF0_ADC0 |

IO or Analog0 |

A5 |

26 |

PF2_ADC2_DIG2 |

IO or Analog2 or SPI CLK |

A6 |

28 |

PF4_ADC4_TCK |

IO or Analog4 or JTAG Test Clock |

A7 |

30 |

PF6_ADC6_TDO |

IO or Analog6 or JTAG Test Data Out or I2C SDA |

A8 |

GND |

Power Supply |

|

B1 |

18 |

PE2_XCK0_AIN0 |

IO or software SPI1 MISO or Analog Comparator or External Clock |

B2 |

19 |

PE3_OC3A_AIN1 |

IO or Analog Comparator or PWM or Output Compare Match |

B3 |

21 |

PE5_OC3C_INT5 |

IO or UART0 RTS Input or PWM or Interrupt |

B4 |

25 |

PF1_ADC1 |

IO or Analog1 or software SPI MOSI |

B5 |

33 |

PG1_DIG1 |

IO |

B6 |

29 |

PF5_ADC5_TMS |

IO or Analog5 or JTAG Test Mode Select |

B7 |

31 |

PF7_ADC7_TDI |

IO or Analog7 or JTAG Test Data In or software I2C SCL |

B8 |

GND |

Power Supply |

|

C1 |

16 |

PE0_RXD0_PCINT8 |

IO or UART0 Data In or Interrupt |

C2 |

17 |

PE1_TXD0 |

IO or UART0 Data Out |

C3 |

20 |

PE4_OC3B_INT4 |

IO or UART0 CTS Output or PWM or Interrupt |

C4 |

22 |

PE6_T3_INT6 |

IO or Interrupt |

C5 |

23 |

PE7_ICP3_INT7_CLK 0 |

IO or UART1 RTS input or Clock Output Buffer or Interrupt |

C6 |

27 |

PF3_ADC3_DIG4 |

IO or ADC channel 3 |

C7 |

NC |

||

C8 |

GND |

Power Supply |

|

D1 |

5 |

PB5_OC1A_PCINT5 |

IO or PWM or Interrupt |

D2 |

6 |

PB6_OC1B_PCINT6 |

IO or PWM or Interrupt |

D3 |

7 |

PB7_OC0A_OC1C_P CINT7 |

IO or PWM or Interrupt |

D4 |

NC |

||

D5 |

NC |

||

D6 |

NC |

||

D7 |

NC |

||

D8 |

GND |

Power Supply |

|

E1 |

2 |

PB2_MOSI_PCINT21 |

IO or Interrupt |

E2 |

3 |

PB3_MISO_PCINT31 |

IO or Interrupt |

E3 |

4 |

PB4_OC2A_PCINT4 |

IO or PWM or Interrupt |

E4 |

NC |

||

E5 |

NC |

||

E6 |

NC |

||

E7 |

NC |

||

E8 |

NC |

||

F1 |

0 |

PB0_SSN_PCINT01 |

IO or Interrupt |

F2 |

1 |

PB1_SCK_PCINT11 |

IO or Interrupt |

F3 |

9 |

PD1_SDA_INT11 |

IO or Interrupt |

F4 |

8 |

PD0_SCL_INT01 |

IO or Interrupt |

F5 |

NC |

||

F6 |

NC |

||

F7 |

NC |

||

F8 |

GND |

Power Supply |

|

G1 |

NC |

||

G2 |

15 |

PD7_T0 |

IO |

G3 |

12 |

PD4_ICP1 |

IO or UART1 CTS output or Input Capture |

G4 |

10 |

PD2_RXD1_INT2 |

IO or UART1 Data In or Interrupt |

G5 |

37 |

PG5_OC0B |

IO or PWM |

G6 |

NC |

||

G7 |

NC |

||

G8 |

GND |

Power Supply |

|

H1 |

GND |

Power Supply |

|

H2 |

14 |

PD6_T1 |

IO or Timer/Counter1 clock input |

H3 |

13 |

PD5_XCK1 |

IO |

H4 |

11 |

PD3_TXD1_INT3 |

IO or UART1 Data Out or Interrupt |

H5 |

RESET# |

Module Reset, Active Low |

|

H6 |

NC |

||

H7 |

NC |

||

H8 |

GND |

Power Supply |

|

1These pins have special I2C and/or SPI hardware that is not natively supported by SNAP. You could use peek and poke to initialize and enable this hardware functionality, but it is not supported by Synapse and we cannot guarantee your results.

Table 3.2: SM200/SNAPpy IO Cross Reference

Pad |

SNAPpy IO |

|---|---|

A4 |

24 |

A5 |

26 |

A6 |

28 |

A7 |

30 |

B1 |

18 |

B2 |

19 |

B3 |

21 |

B4 |

25 |

B5 |

33 |

B6 |

29 |

B7 |

31 |

C1 |

16 |

C2 |

17 |

C3 |

20 |

C4 |

22 |

C5 |

23 |

C6 |

27 |

D1 |

5 |

D2 |

6 |

D3 |

7 |

E1 |

2 |

E2 |

3 |

E3 |

4 |

F1 |

0 |

F2 |

1 |

F3 |

9 |

F4 |

8 |

G2 |

15 |

G3 |

12 |

G4 |

10 |

G5 |

37 |

H2 |

14 |

H3 |

13 |

H4 |

11 |

Electrical Characteristics¶

Table 4.1: SM200 DC Characteristics at 25° C

Symbol |

Parameter |

Condition |

Min |

Typ |

Max |

Units |

VCC1 |

Supply Voltage |

2.0 |

3.3 |

3.6 |

V |

|

TOP |

Operating Temp |

-40 |

85 |

°C |

||

TSTOR |

Storage Temp |

-40 |

125 |

°C |

||

VIH |

Input Hi Voltage |

All Digital Inputs |

0.7 VCC |

V |

||

VIL |

Input Low Voltage |

All Digital Inputs |

0.3 VCC |

V |

||

VOL |

Output Low Voltage |

All drive strengths (2,4,6,8 mA) |

0.4 |

V |

||

VOH |

Output High Voltage |

All drive strengths (2,4,6,8 mA) |

VCC- 0.4 |

V |

||

ILIN |

In Leakage Current |

VIN= VCCor VSS, all Pins |

<10nA |

1 |

µA |

|

TX-ICC |

Transmit Current - Transceiver only |

VCC= 3.3V PTX=3dBm |

14.5 |

mA |

||

Transmit Current - Transceiver and CPU |

22.5 |

mA |

||||

RX-ICC |

Receive Current - Transceiver only |

VCC= 3.3V |

12.5 |

mA |

||

Receive Current - Transceiver and CPU |

20.5 |

mA |

||||

SHDN- ICC |

VCC= 3.3V |

0.37 |

µA |

1Absolute maximum stress rated voltage for VCC is -0.3 to 3.6. It is recommended that bulk capacitance be located as close as possible to the VCC pin on the host board. Ideally, use a single 47µF capacitor at 10V directly at the VCC pin.

Table 4.2: ADC Electrical Characteristics (Operating)

VREFH1 |

ADC Voltage Reference, High |

Programmable |

1.5 |

1.6 |

1.8 |

V |

VINDC |

Analog input voltage |

Single Ended |

0 |

1.8 |

V |

|

Differential2 |

0 |

3.3 |

V |

Table 4.3: ADC Timing/Performance Characteristics

Symbol |

Parameter |

Condition |

Min |

Typical |

Max |

Unit |

|---|---|---|---|---|---|---|

RAS |

Source impedance at input1 |

3k |

kΩ |

|||

RES |

Conversion Resolution |

Single Ended CLKADC <= 4MHz |

10 |

Bits |

||

DNL |

Differential non- linearity |

VREFH = 1.6V CLKADC=4MHz |

-0.5 |

LSB |

||

INL |

Integral non- linearity |

VREFH = 1.6V CLKADC=4MHz |

0.8 |

LSB |

||

EZS |

Zero-scale error |

1.5 |

LSB |

|||

EG |

Gain error |

1 |

LSB |

1Any analog source with a source impedance greater than 3kΩ will increase the sampling time.

Table 4.4: Reset, Brown-out and Internal Voltage Characteristics

Symbol |

Parameter |

Condition |

Min |

Typical |

Max |

Unit |

VPOT (rising) |

Power-on Reset Threshold Voltage (rising) |

Power supply fully discharged |

1.6 |

V |

||

VPOT (falling) |

Power-on Reset Threshold Voltage (falling) |

0.05 |

0.3 |

V |

||

tPOT |

Power-on Reset recovery time |

Time of EVDD/DEVDD < VPOT |

1 |

ms |

||

VPSR |

Power-on slope rate |

1.8 |

3300 |

V/ms |

||

VRST |

RSTN Pin Threshold Voltage |

0.1VDD |

0.9 VDD |

V |

||

tRST |

Minimum pulse width on RSTN Pin |

200 |

300 |

ns |

||

VHYS |

Brown-out Detector Hysteresis |

7.5 |

50 |

mV |

||

tBOD |

Min Pulse Width on Brown-out Reset |

100 |

ns |

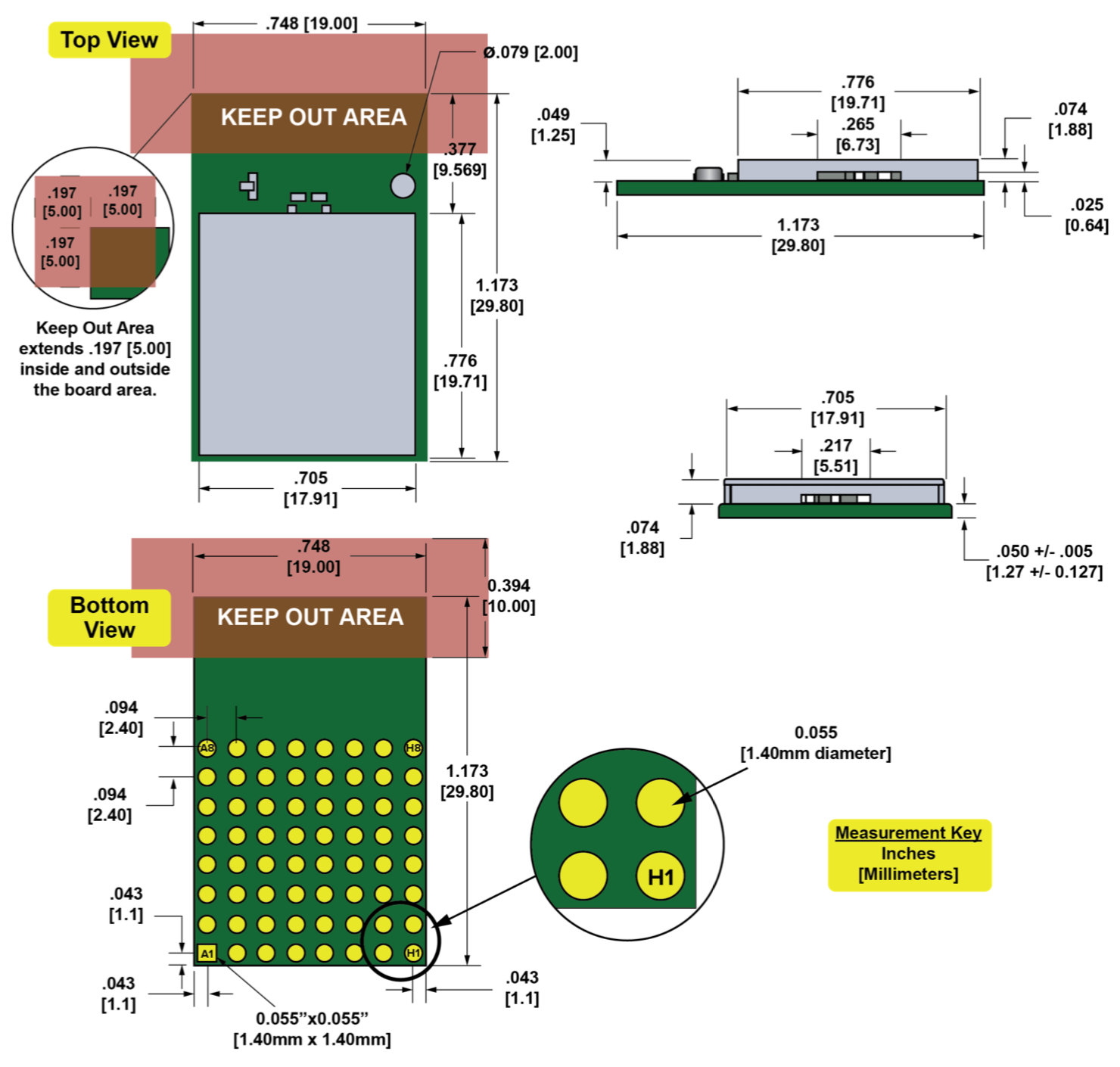

Mechanical Drawings¶

The drawings below show the modules with the option of the integrated chip antenna or U.FL Connector.

Note

The area under the module’s antenna (marked NO COPPER or KEEP OUT AREA) should have no components, no traces, and no copper on any layer of the printed circuit board.

SM200PF1/PU1 Mechanical Drawing¶

Note

Metric measurements in millimeters are between brackets, with standard measurements in inches below.

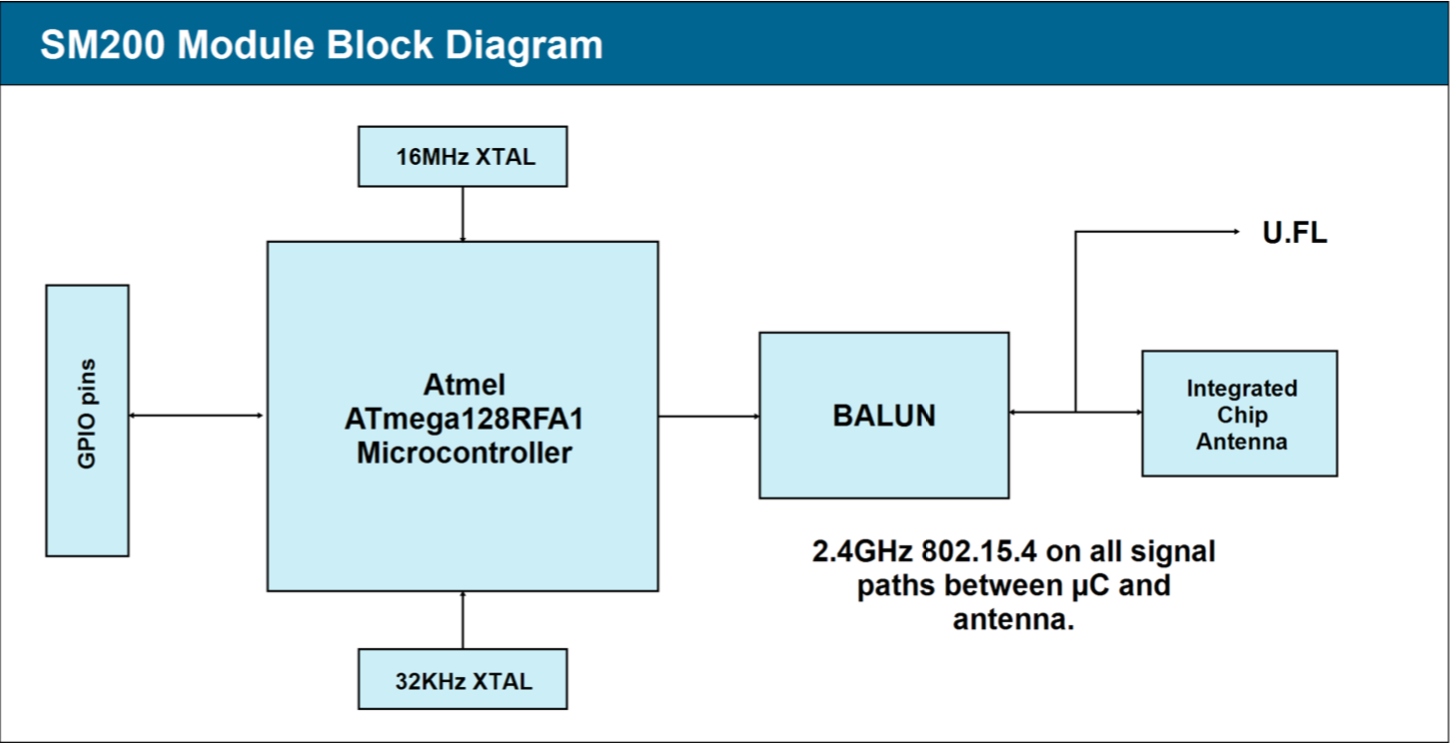

Block diagram showing the major subsystems comprising Model SM200¶

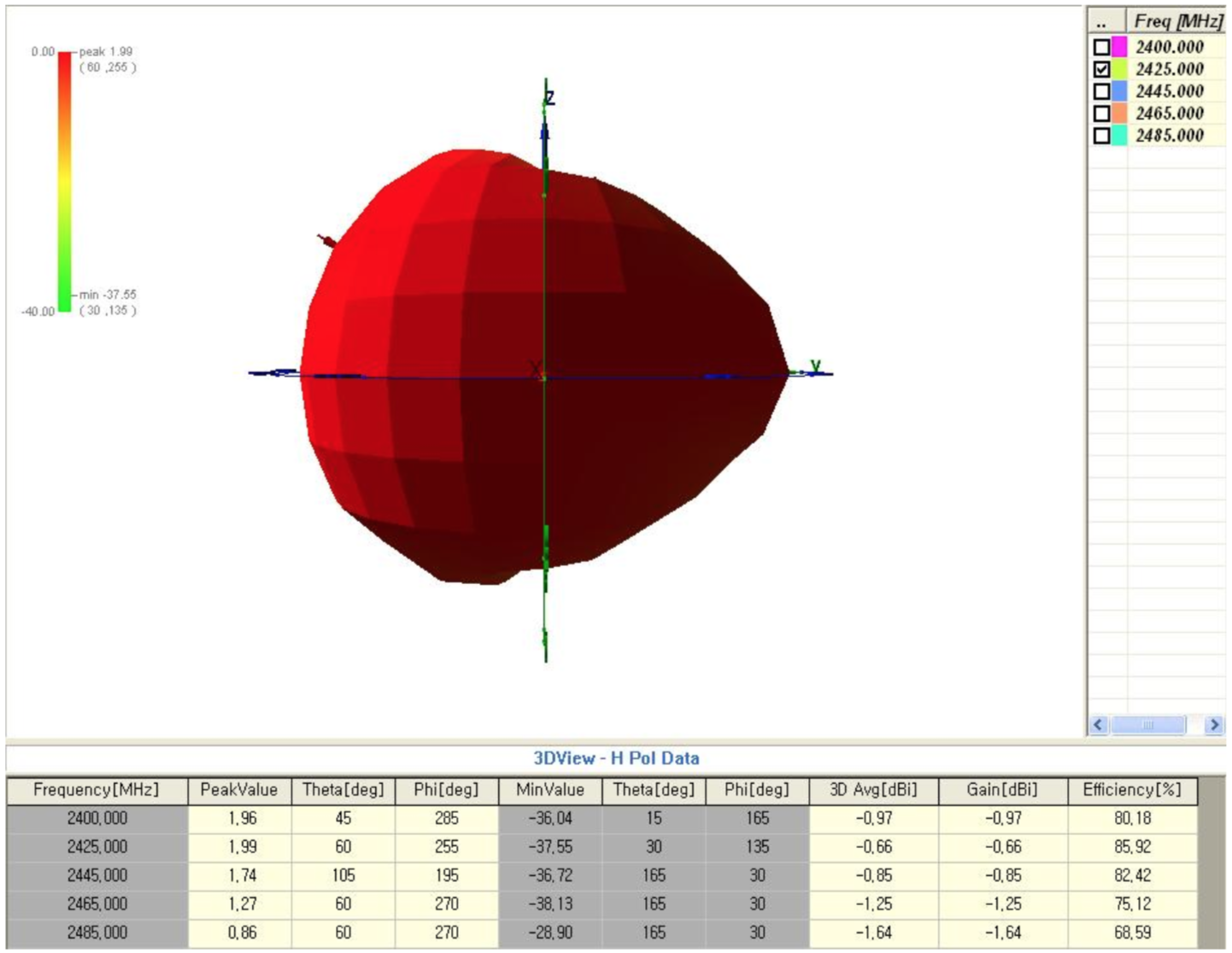

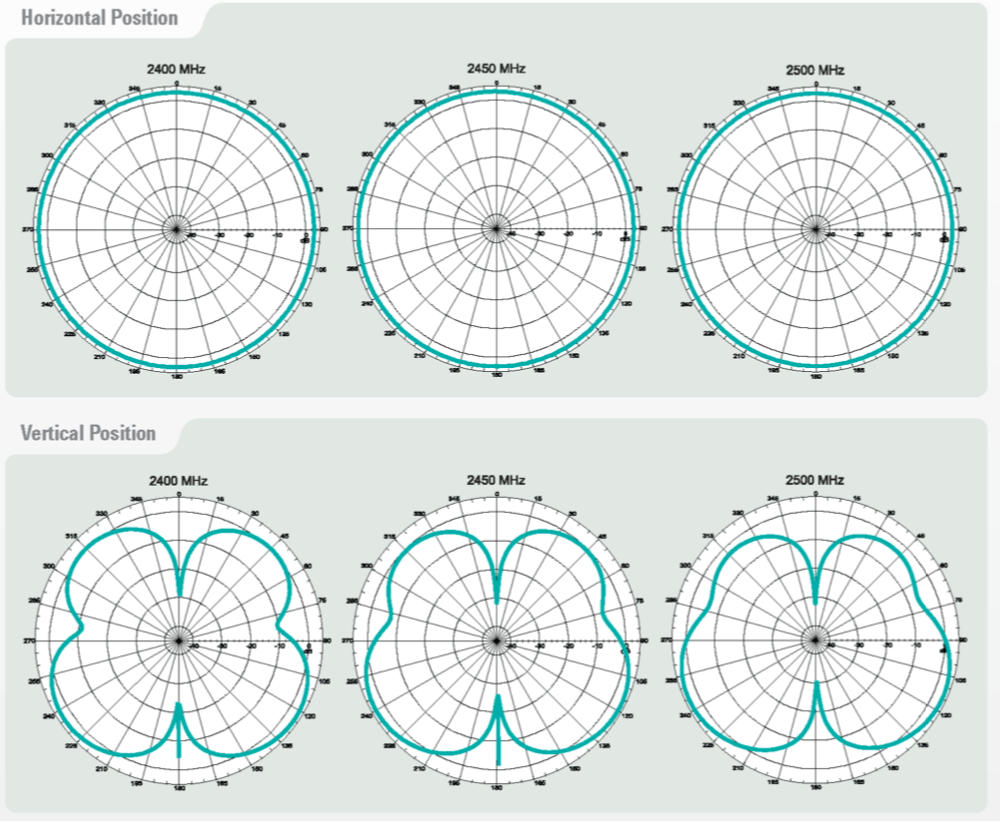

Antenna Gain Performance¶

Note

Antenna gain performance information is based on information from the individual companies at the time this document’s release. For added assurance, it’s best to obtain antenna performance information directly from that antenna’s manufacturer.

Partron SDBTPTR3015 Antenna Gain Performance¶

Pulse W1027 Antenna Gain Performance¶

Board Mounting Considerations¶

Processing¶

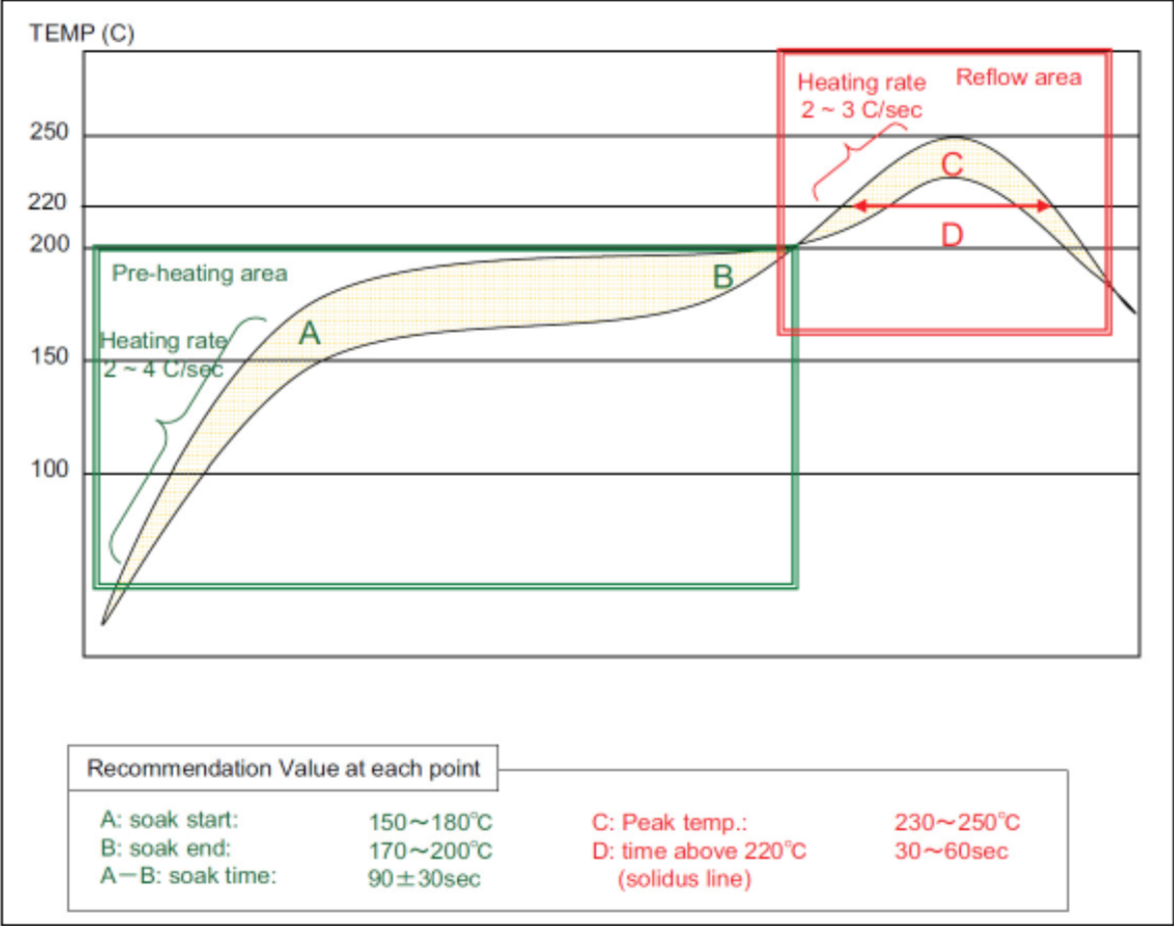

Table 7.1: Recommended Reflow Profile

Parameter |

Value |

|---|---|

Ramp up rate (from Tsoakmax to Tpeak) |

3°/sec max |

Minimum Soak Temperature |

150°C |

Maximum Soak Temperature |

200°C |

Soak Time |

60-120 sec |

TLiquidus |

217°C |

Time above TL |

30-60 sec (recommended: 40 sec) |

Tpeak |

230° - 250°C (recommended: 235oC) |

Time within 5° of Tpeak |

20-30 sec |

Time from 25° to Tpeak |

8 min max |

Ramp down rate |

6°C/sec max |

Pb-Free Soldering Paste¶

Use of “No Clean” soldering paste is strongly recommended, as it does not require cleaning after the soldering process.

Cleaning¶

In general, cleaning the populated modules is strongly discouraged. Residuals under the module cannot be easily removed with any cleaning process.

Cleaning with water can lead to capillary effects where water is absorbed into the gap between the host board and the module. The combination of soldering flux residuals and encapsulated water could lead to short circuits between neighboring pads. Water could also damage any stickers or labels.

Cleaning with alcohol or a similar organic solvent will likely flood soldering flux residuals into the two housings, which is not accessible for post-washing inspection. The solvent could also damage any stickers or labels.

Ultrasonic cleaning could damage the module permanently.

The recommended approach is to consider using a “no clean” soldering paste and eliminate the post-soldering cleaning step.

Repeating Reflow Soldering¶

Only a single reflow soldering process is encouraged for host boards.

Rework¶

The Model SM200 Module can be unsoldered from the host board, but the process is likely to damage the chip and not recommended. If attempting this, use of a hot air rework tool and hot plate for pre-heating from underneath is recommended. Avoid overheating.

Warning

Never attempt a rework on the module itself (e.g. replacing individual components). Such actions will terminate warranty coverage.

Additional Grounding¶

Attempts to improve module or system grounding by soldering braids, wires, or cables onto the module RF shield cover is done at the customer’s own risk. The numerous ground pins at the module perimeter should be sufficient for optimum immunity to external RF interference.

Packaging¶

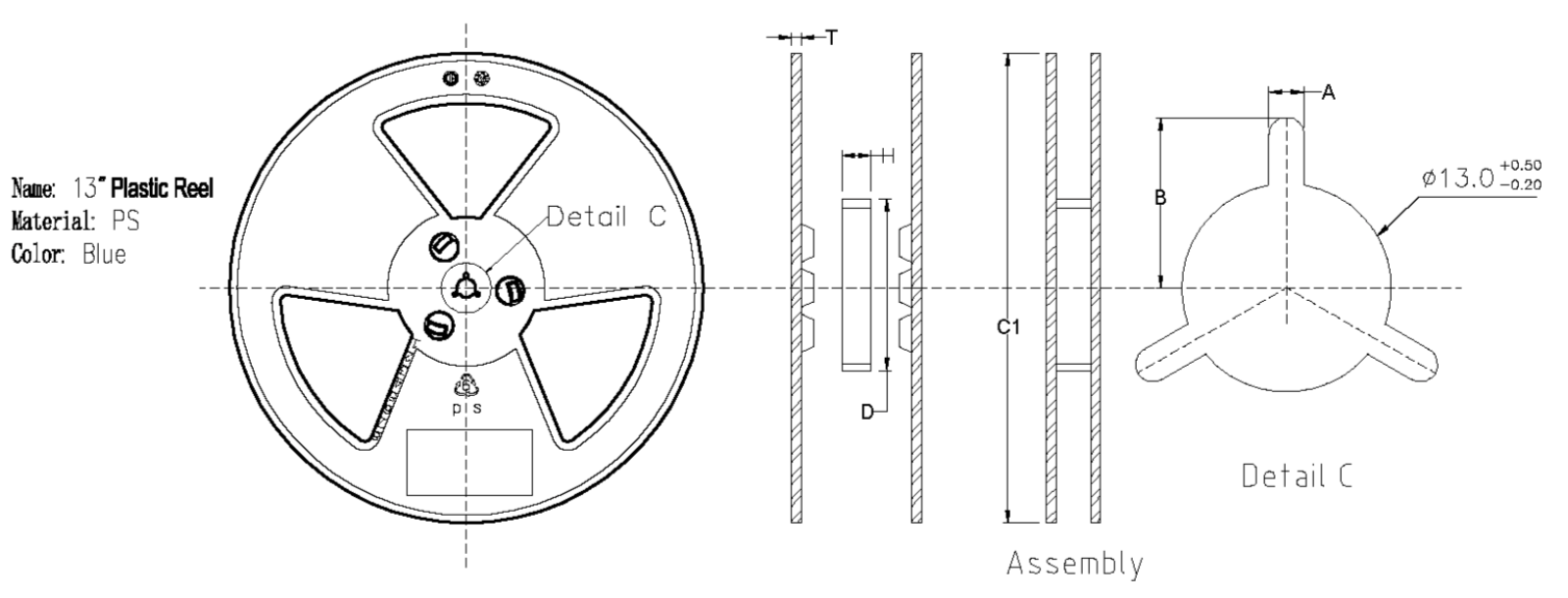

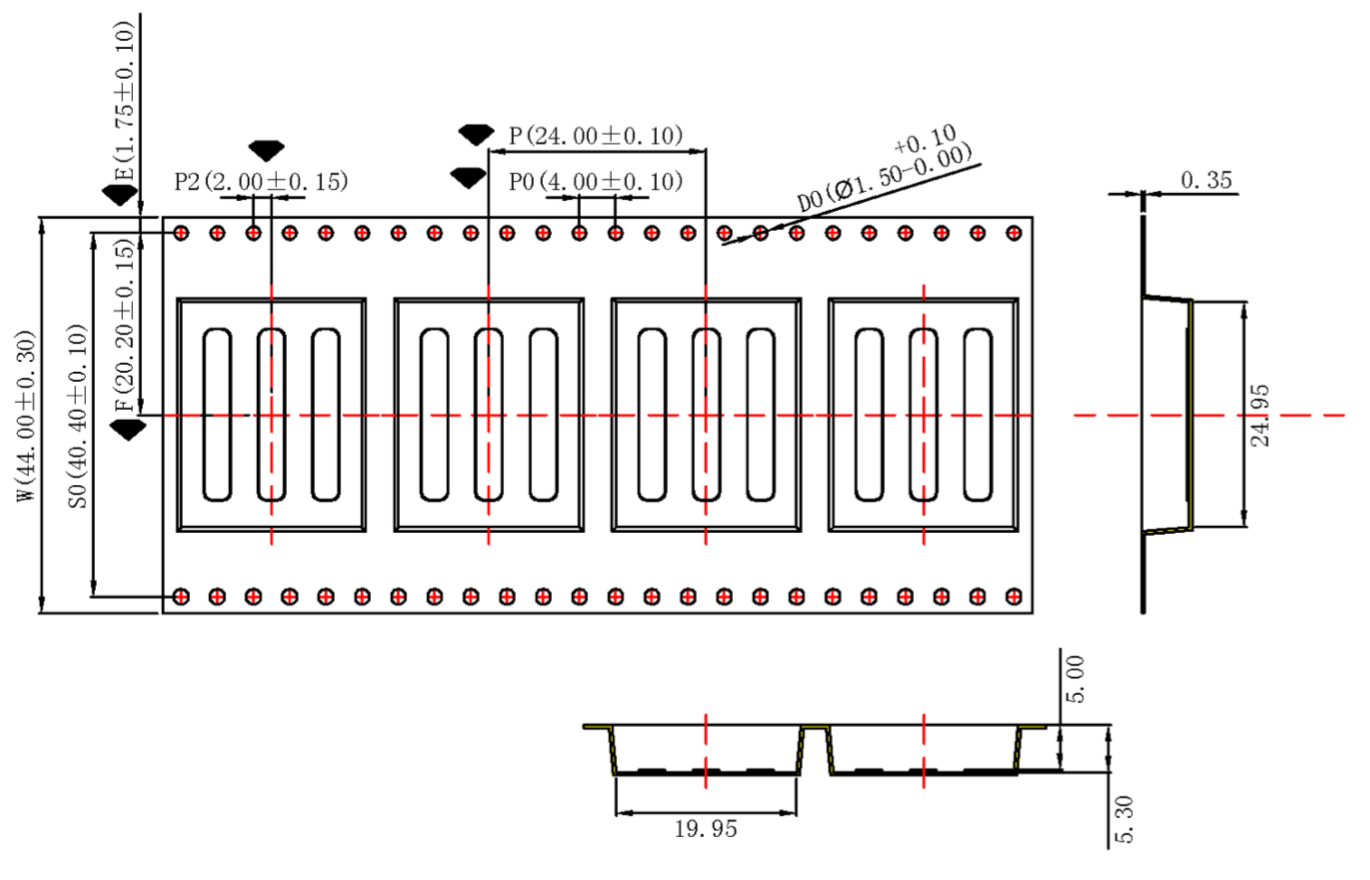

Synapse SM series modules are available on plastic reels of carrier tape. The dimensions for those reels are provided below.

H+/-0.5 |

C1+/-1.0 |

A+/-0.2 |

C+0.5 -0.2 |

T+/-0.3 |

B+/-0.2 |

D+/-2.0 |

|---|---|---|---|---|---|---|

44.5 |

ø330 |

2.2 |

13 |

2.2 |

10.75 |

99.5 |

All dimensions are in mm.

Sprocket hole pitch cumulative tolerance: +/-0.2mm.

Carrier camber not to exceed 1mm in 250mm.

All dimensions meet EIA-481-C requirements.

Thickness: 0.35mm +/- 0.05mm.

Packing length per reel: 12.6 meters.

Component load per reel: 500 pieces.

Agency Certifications¶

United States (FCC)¶

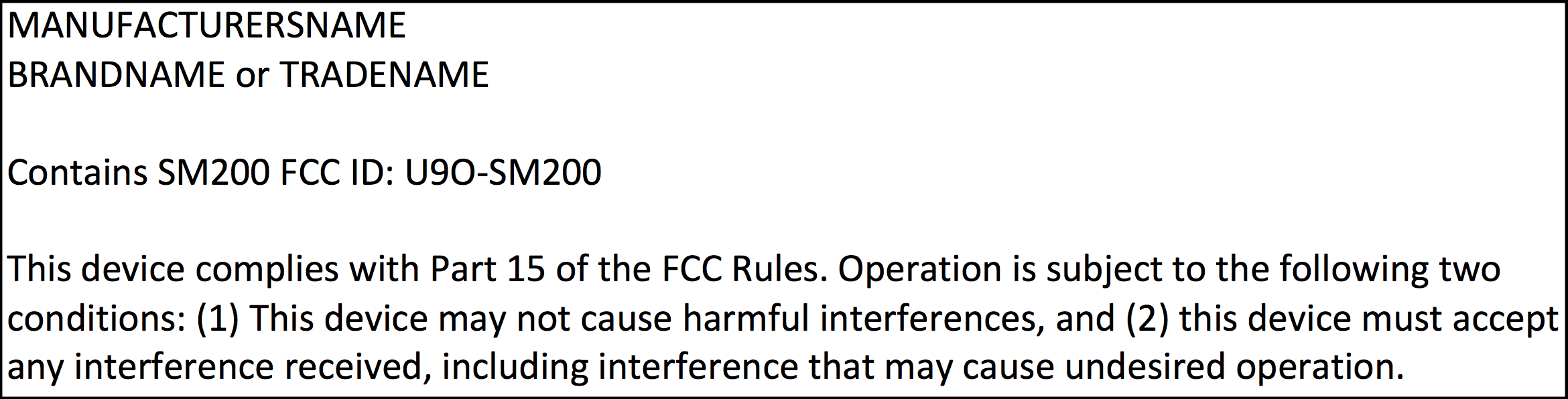

The Model SM200 modules comply with Part 15 of the FCC rules and regulations. Compliance with the labeling requirements, FCC notices, and antenna usage guidelines is required. In order to comply with FCC Certification requirements, the Original Equipment Manufacturer (OEM) must fulfill the following requirements.

The system integrator must place an exterior label on the outside of the final product housing the SM200 Modules. FCC Label below shows the contents that must be included on this label.

SM200 Modules may only be used with the antenna that has been tested and approved for use with the module. Please refer to the antenna table provided in this section.

OEM Labeling Requirements¶

NOTICE: The OEM must make sure that FCC labeling requirements are met. This includes a clearly visible exterior label on the outside of the final product housing that displays the contents shown in FCC Label below.

FCC Label¶

FCC Notices¶

Warning

The SM200 modules have been tested by the FCC for use with other products without further certification (as per FCC Section 2.1091). Changes or modifications to this device not expressly approved by Synapse Wireless Inc. could void the user’s authority to operate the equipment.

NOTICE: OEM’s must certify final end product to comply with unintentional radiators (FCC Sections 15.107 and 15.109) before declaring compliance of their final product to Part 15 of the FCC Rules.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy, and if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Approved Antennas¶

The SM200 modules are FCC-approved for fixed base station, mobile, and portable applications.

NOTICE: To reduce potential radio interference to other users, the antenna type and its gain should be chosen so that the equivalent isotropically radiated power (EIRP) is not more than that permitted for successful communication. This module has been designed to operate with the antennas listed in SM200 Approved FCC Antennas above. The required antenna impedance is 50 ohms.

In order to comply with FCC/ISED RF Exposure requirements, this device must be installed to provide at least 20 cm separation from the human body at all times.

Table 8.1: SM200 Approved FCC Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Partron SDBTPTR3015 |

Chip |

1.96 dBi |

Fixed/Mobile |

20 cm. |

Table 8.2: SM200 Approved FCC Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Pulse W1027 |

Dipole (quarter-wave RPSMA) |

3.2 dBi |

Fixed/Mobile |

20 cm. |

For more information on approved antennas, please consult the manufacturer’s website.

Note

Antenna and transmitters may be co-located or operated in conjunction with this device only if the transmitters do not simultaneously transmit. Otherwise, additional regulatory requirements will apply.

Canada (IC)¶

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power (EIRP) is not more than that necessary for successful communication.

Conformément à la réglementation d’Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d’un type et d’un gain maximal (ou inférieur) approuvé pour l’émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l’intention des autres utilisateurs, il faut choisir le type d’antenne et son gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l’intensité nécessaire à l’établissement d’une communication satisfaisante.

This radio transmitter Model: SM200, IC: 7084A-SM200 has been approved by Industry Canada to operate with the antenna types listed below with the maximum permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having a gain greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Le présent émetteur radio Model : SM200, IC : 7084A-SM200 a été approuvé par Industrie Canada pour fonctionner avec les types d’antenne énumérés ci-dessous et ayant un gain admissible maximal et l’impédance requise pour chaque type d’antenne. Les types d’antenne non inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l’exploitation de l’émetteur.

In order to comply with FCC/ISED RF Exposure requirements, this device must be installed to provide at least 20 cm separation from the human body at all times.

Afin de se conformer aux exigences d’exposition RF FCC / ISED, cet appareil doit être installé pour fournir au moins 20 cm de séparation du corps humain en tout temps.

Table 8.3: SM200 Approved IC Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Partron SDBTPTR3015 |

Chip |

1.96 dBi |

Fixed/Mobile |

20 cm. |

Table 8.4: SM200 Approved IC Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Pulse W1027 |

Dipole (quarter-wave RPSMA) |

3.2 dBi |

Fixed/Mobile |

20 cm. |

CE Approved Antennas¶

The SM200 modules are CE-approved for fixed base station and mobile applications.

NOTICE: To reduce potential radio interference to other users, the antenna type and its gain should be chosen so that the equivalent isotropically radiated power (EIRP) is not more than that permitted for successful communication. This module has been designed to operate with the antennas listed in SM200 Approved FCC Antennas above. The required antenna impedance is 50 ohms.

In order to comply with FCC/ISED RF Exposure requirements, this device must be installed to provide at least 20 cm separation from the human body at all times.

Table 8.5: SM200 Approved CE Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Partron SDBTPTR3015 |

Chip |

1.96 dBi |

Fixed/Mobile |

20 cm. |

Table 8.6: SM200 Approved CE Antennas

Part Number |

Type |

Gain |

Application |

Min. Separation |

|---|---|---|---|---|

Pulse W1027 |

Dipole (quarter-wave RPSMA) |

3.2 dBi |

Fixed/Mobile |

20 cm. |

For more information on approved antennas, please consult the manufacturer’s website.

Note

Antenna and transmitters may be co-located or operated in conjunction with this device only if the transmitters do not simultaneously transmit. Otherwise, additional regulatory requirements will apply.

IC OEM Labeling Requirements¶

Labeling requirements for Industry Canada are similar to those of the FCC. A clearly visible label on the outside of the final product housing must display the contents shown in IC Label below.

IC Label¶

Note

The OEM can choose to implement a single label combined for both FCC and IC labeling requirements. If a combined single label is chosen, there must be a clearly visible label on the outside of the final product housing displaying the contents shown in Combined FCC and IC Label below.

Combined FCC and IC Label¶

OEM Labeling Requirements for the European Union¶

The “CE” mark must be placed on the OEM product in a visible location. The CE mark will consist of the Initials “CE” with the following form:

If the CE marking is reduced or enlarged, the proportions given in the following drawing must be adhered too.

The CE mark must be a minimum of 5mm in height.

The CE marking must be affixed visibly, legibly, and indelibly.

Since the 2400-2483.5 MHz band is not harmonized by a few countries throughout Europe, the Restriction sign must be placed to the right of the CE marking as shown in the drawing.

Note

The OEM can choose to implement a single label combined for FCC, CE and IC labeling requirements. If a combined single label is chosen, there must be a clearly visible label on the outside of the final product housing displaying the contents shown in Combined FCC, CE and IC Label above.

Combined FCC, CE and IC Label¶